Flat roofs, abundant on commercial buildings, industrial facilities, and modern residences, have become prime real estate for solar energy adoption—thanks to specialized flat roof solar panel mounting systems. These engineered solutions address the unique challenges of flat surfaces, unlocking their full potential for clean energy generation while ensuring structural safety and operational efficiency.

Unlike sloped roof systems that rely on gravity and roof pitch, flat roof mounting systems prioritize flexibility and stability. Most utilize two core designs: ballasted systems and penetrative systems. Ballasted systems, the more popular choice, use concrete blocks, water tanks, or weighted frames to secure panels without drilling into the roof membrane—preserving waterproofing and avoiding structural damage. Penetrative systems, ideal for roofs with robust structural support, use fasteners anchored to the roof deck for enhanced wind resistance, suitable for high-wind regions. Both designs offer adjustable tilt angles (typically 10-30 degrees) to optimize sun exposure, maximizing energy output throughout the day.

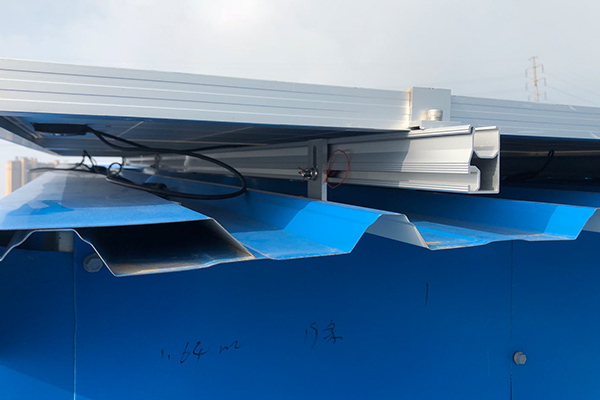

Versatility and space efficiency are key strengths of these mounting systems. Modular components allow for customizable layouts, adapting to irregular roof shapes, HVAC units, or skylights. By arranging panels in optimal configurations—such as portrait or landscape orientation—installers can maximize the number of panels per square meter, boosting energy yield for limited roof spaces. Many systems also feature height-adjustable rails, facilitating airflow beneath panels to reduce heat buildup, which can degrade panel performance over time.

Durability and compatibility further elevate their appeal. Constructed from corrosion-resistant materials like aluminum and stainless steel, these systems withstand harsh weather conditions—from extreme temperatures to heavy rainfall—ensuring long-term reliability. They are compatible with all solar panel types, including monocrystalline, polycrystalline, and thin-film, making them a flexible choice for both new installations and retrofits. Additionally, modern systems integrate seamlessly with solar inverters and monitoring tools, enabling real-time performance tracking and maintenance.

For businesses and homeowners alike, flat roof solar mounting systems offer a cost-effective path to sustainability. They eliminate the need for roof modifications in many cases, reducing installation time and labor costs. By harnessing unused roof space to generate electricity, users lower energy bills, qualify for renewable energy incentives, and reduce their carbon footprint. As the demand for solar energy grows, these mounting systems continue to evolve—with innovations in lightweight materials and smart design—solidifying their role as a cornerstone of efficient, accessible renewable energy solutions.